gUSTAFS

Creating new composite materials and 3D-printing acoustic panels from manufacturing waste

Working with Gustafs — a leading Swedish manufacturer of wooden panels and fittings for public interiors — and with the help of the additive manufacturing experts at CircLab, we developed new wood based composite materials for 3D-printing out of waste streams coming from the production at the Gustafs factory. These materials where then used to 3D-print acoustic panels and diffusors in a variety of shapes. Much of Gustafs output takes the shape of linear panels mostly consisting of recycled materials. The surface however is clad in a thin strip of high quality veneer, made out of a variety of different trees.

During the production process small pieces of veneer are cut off to be fitted to the panels. These pieces have previously been thought to be too small to be reused in a different application. Experimenting with different veneers and material formulas we crafted a custom walnut based wood composite by mixing wood with biodegradable resin.

Dreams of circular manufacturing

Gustafs is a leading Swedish manufacturer of sophisticated wooden panels and fittings for public interiors. Founded in 1913 and located in a town with the same name, Gustafs now creates acoustic environments for concert halls, schools, offices and public buildings throughout Scandinavia and Europe.

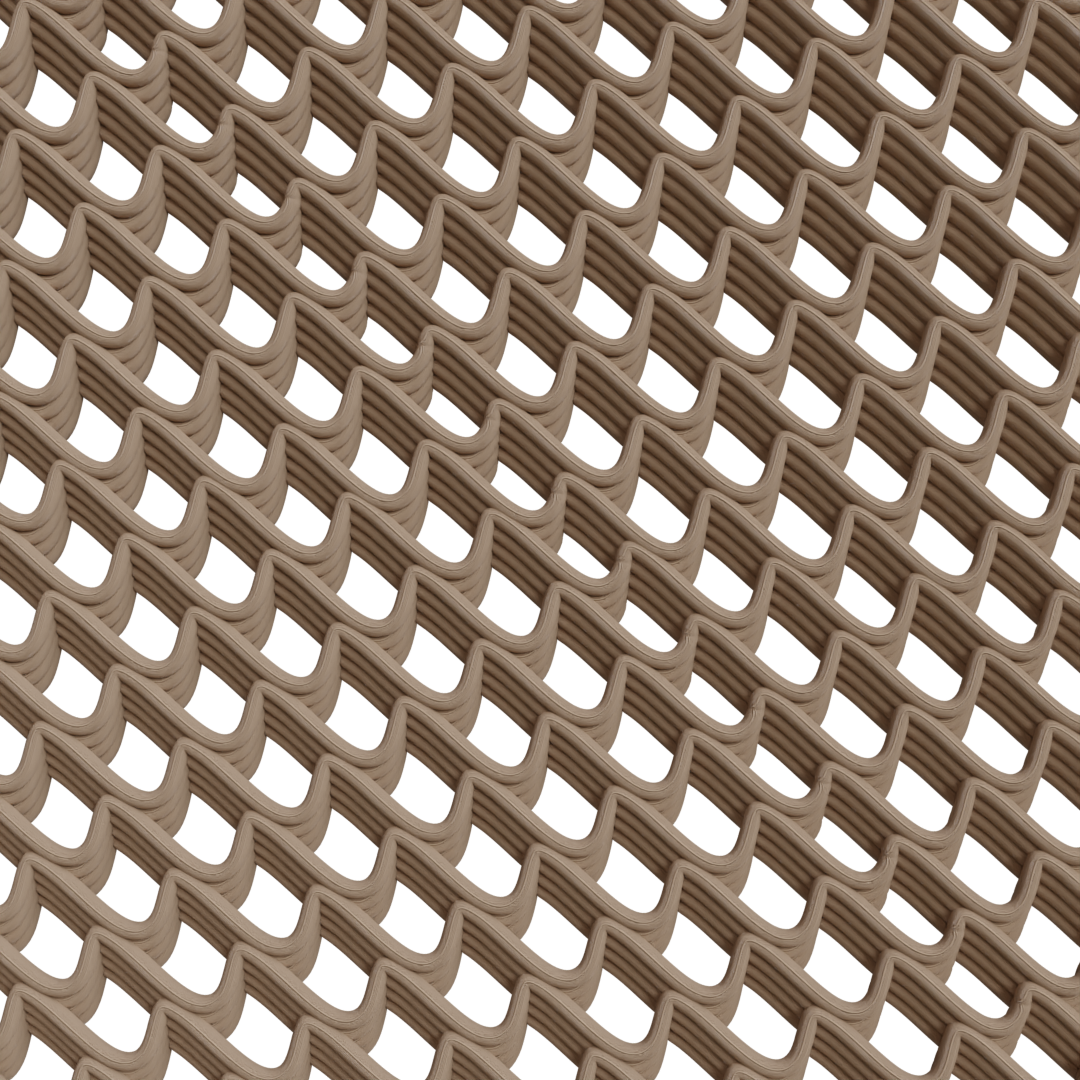

A large focus of the project was to create visually eye-catching yet production-effective shapes that could be used in a public environment, filling a variety of roles as a complement to Gustafs standard product range.

During the design process a number of different designs where developed and tested, both acoustic panels with a bottom layer made out of felt, aswell as sound diffusers created to spread out incoming sound waves inside large spaces.